FR(Flame Retardant) / Industrial Yarn & Fabric

Flame retardant products with excellent protection from fire and heat!

Home

-Products

-Industrial

/ Flame Retardant Fabric

Military Fabric

Flame retardant products with excellent protection from fire and heat!

This product will guarantee you absolute protection from fire and heat with its outstanding properties of Flame Resistance, fire retardant, and practicality.

Fabric for special fireproof suits, balaclava and gloves for firefighting using poly-benzimidazole (PBI) materials from PBI Performance Products.

| PBI | RIm-ARAMIDNG | p-ARAMID | |

|---|---|---|---|

| Limiting oxygen index(LOI) | 43% | 29% | 25~28% |

| Pyrolysis temperature | 720c | 400c | 550c |

| Strength(g/d) | Low 2.9 | Low 2.9~7.2 | Very high 22~36 |

| Chemical resistance | Very high | Normal | Normal |

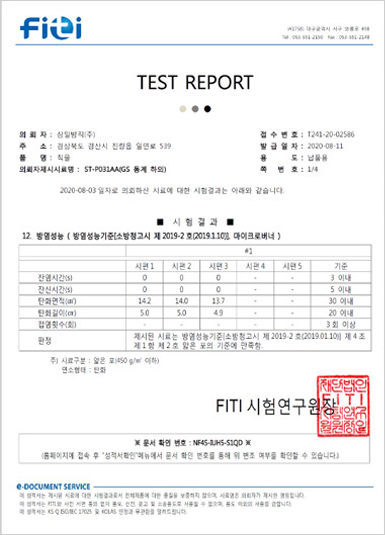

Fabric with superb fire retardancy performance with blend of LENZING FR and Aramid. Achieves performance of fabrics used in uniforms for the forest firefighter squad and the volunteer firefighter squad.

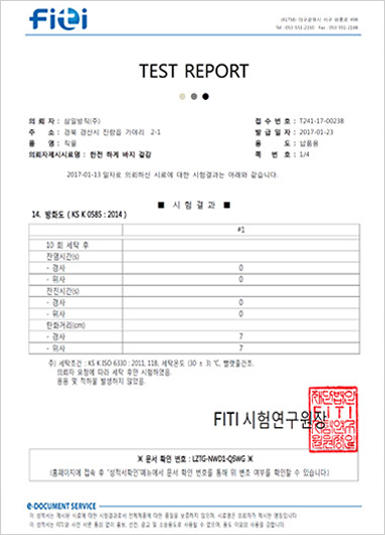

It is a fabric that does not require separate flame-retardant processing (post-processing) and offers semi-permanent fire resistance without decrease in performance after washing, etc. The fabric does not require a separate fabric dyeing process. It is a fabric used in human-friendly fire-resistant civil defense training uniforms with superb color fastness (sunlight, washing, friction) offered at a competitive price.

Permanent fire retardancy

High reliability

Comfortable wear

Pleasant ventilation

Industrial flame retardant

aramid, Cellulose-FR

Application

Resistant to chemicals, fire and molten metal,Welding Suit, Combat Suit, Fire-fighting suit, etc

Industrial protective clothing

Modacrylic, Aramid, Cellulose

Application

Molten Metal, Electric Arc, Welding, Flame resistance, Chemical Suits, etc

Industrial safety clothing

Modacrylic, Cellulose

Application

Flame resistance, Chemical Suits, Welder

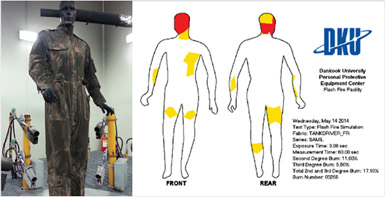

Once exposed to fire, the human body suffers severe burn damage from continuously growing flame and melting polyester. Also, wearing a burning workwear makes it difficult to initially respond to sudden fires.

Once exposed to fire, the human body suffers severe burn damage from continuously growing flame and melting polyester. Also, wearing a burning workwear makes it difficult to initially respond to sudden fires.

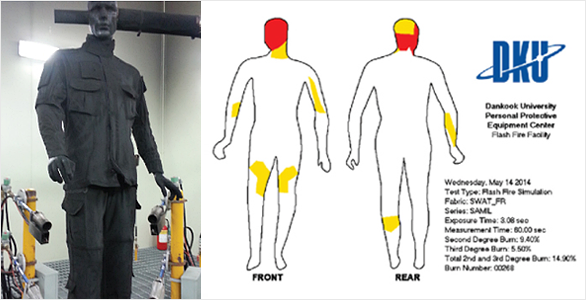

It is used in army pilot uniforms, police SWAT uniforms, Black Eagles Pilot uniforms, etc.

「High Tech Spun Dyed FR Yarn and Fabric」 is a product that has several advantages compared to the traditional FR yarn and fabric with application of solution-dyeing technology.

Eco-friendly fire-resistant fabric without necessity for dyeing can be delivered within a short period of time and maintains consistent quality even for small orders superb fire resistance and color fastness

Eco-friendly manufacturing method : there is no need for a dyeing process, which can reduce use of water and chemicals in fabric manufacturing and does not generate chemical wastes as it minimizes energy consumption to reduce CO2 emission.

Eco-Friendly, Dramatic reduction in Carbon Foot Print

(Water reduction, Energy reduction, Increase garment longevity)

Quick Response, Quick Delivery

Small lots with same quality

Excellent color fastness to light

Excellent color fastness to friction

Excellent color fastness to washing

Cost savings in total supply chain cost integration

Black

Gray

Navy

Blue

Red

Orange

Hi-vis Yellow

Khaki

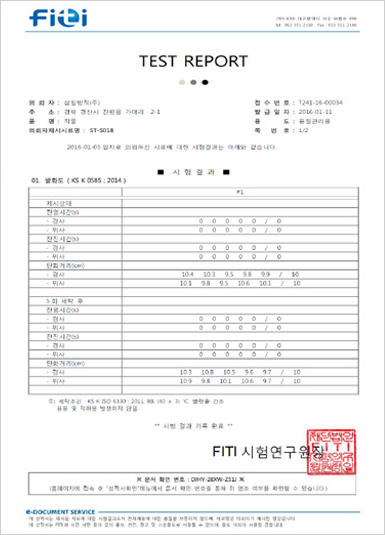

| #1 | |

|---|---|

| COLOR CHANGE | 4-5 |

| COLOR STAINING | |

| -ACRYLIC | 4-5 |

| -VISCOSE | 4-5 |

| #1 | |

|---|---|

| ACID | |

| COLOR CHANGE | 4-5 |

| COLOR STAINING | |

| -ACRYLIC | 4-5 |

| -VISCOSE | 4-5 |

| ALKALI | |

| COLOR CHANGE | 4-5 |

| COLOR STAINING | |

| -ACRYLIC | 4-5 |

| -VISCOSE | 4-5 |

| #1 | |

|---|---|

| DRY | 4-5 |

| WET | 4 |

| #1 | |

|---|---|

| BLUE WOLL REFERENCE 4 | ABOVE |

| #1 | |

|---|---|

| COLOR CHANGE | 4-5 |

| COLOR STAINING | |

| -ACRYLIC | 4-5 |

| -VISCOSE | 4-5 |

| #1 | |

|---|---|

| ACID | |

| COLOR CHANGE | 4-5 |

| COLOR STAINING | |

| -ACRYLIC | 4-5 |

| -VISCOSE | 4-5 |

| ALKALI | |

| COLOR CHANGE | 4-5 |

| COLOR STAINING | 4-5 |

| -ACRYLIC | 4-5 |

| -VISCOSE | 4-5 |

| #1 | |

|---|---|

| DRY | 4-5 |

| WET | 4 |

| #1 | |

|---|---|

| BLUE WOLL REFERENCE 4 | ABOVE 4 |

NevurN

It is a combination of the words ‘Never’ and ‘Burn’ and a complex spun yarn and fabric made from SAMIL Spinning technology.